Presse à poinçonner en acier CNC 160T industrielle, presse à poinçonner économe en énergie

Description du produit

1. Puissance et capacité

La presse à poinçonner en acier CNC 160T industrielle possède une capacité de pression de 160 tonnes, ce qui lui permet de gérer facilement les tâches de poinçonnage d'acier lourdes. Elle peut traiter efficacement divers matériaux en acier, des tôles minces aux plaques relativement épaisses, répondant aux diverses exigences de production dans des industries telles que l'automobile, l'aérospatiale et la construction.

2. Intégration de la technologie CNC

Équipée d'une technologie de contrôle numérique par ordinateur (CNC) avancée, cette presse à poinçonner permet des opérations hautement précises et automatisées. Le système CNC assure un positionnement et un poinçonnage précis, réduisant les erreurs et améliorant la qualité globale des produits poinçonnés. Il permet également une programmation et un réglage faciles pour différents motifs et spécifications de poinçonnage.

3. Fonction d'économie d'énergie

En tant que presse à poinçonner économe en énergie, elle est conçue avec des composants et des systèmes écoénergétiques. Par rapport aux presses à poinçonner traditionnelles, elle consomme moins d'électricité pendant le fonctionnement, aidant les entreprises à réduire les coûts énergétiques et à atteindre les objectifs de durabilité environnementale. La conception économe en énergie ne compromet pas ses performances, maintenant une efficacité et une productivité élevées.

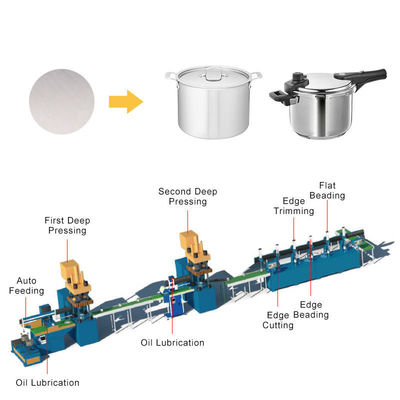

4. Polyvalence et application

Cette presse à poinçonner est très polyvalente et peut être utilisée pour une large gamme d'applications de poinçonnage d'acier, y compris le poinçonnage de trous, l'entaillage et le formage. Son adaptabilité la rend adaptée à différentes lignes de production et processus de fabrication, améliorant la flexibilité de la production et permettant aux fabricants de répondre rapidement aux demandes du marché.

Paramètres du produit

| Pression nominale |

400KN |

| Course du coulisseau |

100MM |

| Puissance du moteur |

4000W |

| Nombre de courses |

45 fois/min |

| Hauteur de fermeture maximale |

330mm |

| Réglage de la distance entre le bas du coulisseau et la table de travail |

50mm |

| Distance du centre du coulisseau au corps |

500mm |

| Taille de l'établi avant et arrière*gauche et droite |

640mm*420mm |

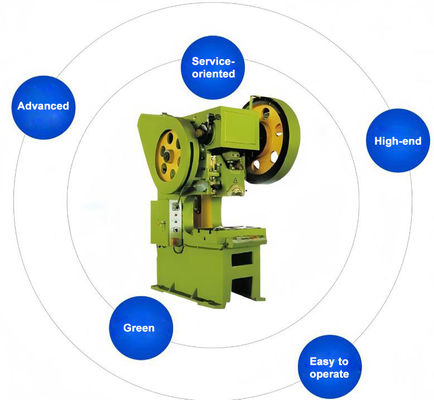

Nos Avantages

Notre équipe est engagée dans l'industrie de la fabrication de matériel depuis plus de 20 ans, en se concentrant sur la fourniture d'équipements de ligne de production et de support technique pour les produits d'éviers de cuisine et les produits de quincaillerie de cuisine. Nous maîtrisons l'ensemble de la technologie de la ligne de production des usines de matériel, y compris le laminage de bobines métalliques, le traitement thermique, les matrices d'estampage, la découpe laser, le rainurage, le pliage, le soudage, le meulage, le polissage, le nettoyage, la pulvérisation, etc. Depuis notre entrée dans le commerce extérieur il y a plus de dix ans, nous avons fourni des équipements de ligne de production, des moules et un support technique de pointe uniques aux fabricants de matériel du monde entier. Nos avantages sont les suivants : Le professionnalisme crée de la valeur. Technologie de pointe, services professionnels efficaces tout au long du processus et les prix les plus compétitifs.

Notre principe est : Devenir le partenaire technique le plus fiable des fabricants de matériel du monde !

Service après-vente

Nous nous engageons à vous fournir un service après-vente complet et de haute qualité, afin que vous n'ayez aucun souci lors de l'utilisation de nos produits.

Nous sommes bien conscients de l'importance du service après-vente pour les clients et adhérons toujours au principe centré sur le client et résolvons les problèmes pour vous avec un service professionnel, efficace et attentionné. Choisir nos produits, c'est choisir un sentiment de sécurité et de garantie.

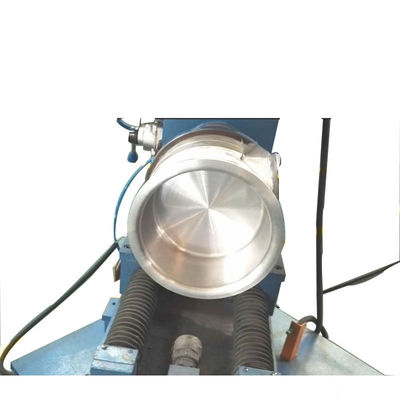

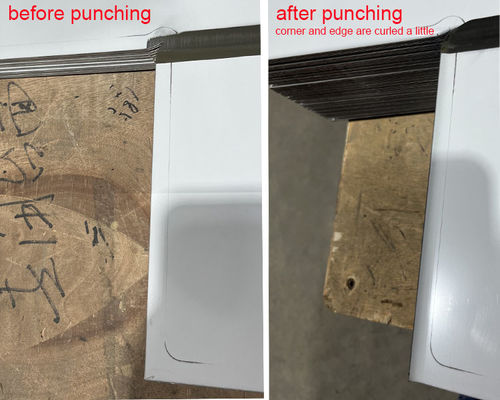

Photos du produit

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!